We think zinc and create growth

At Linimatic A/S we create growth and value with zinc – both here and abroad. Since 1967 we have specialised in die-cast zinc, because we know that this metal has many advantages when special parts are to be used. It is, in brief, a good business strategy to think zinc from the start.

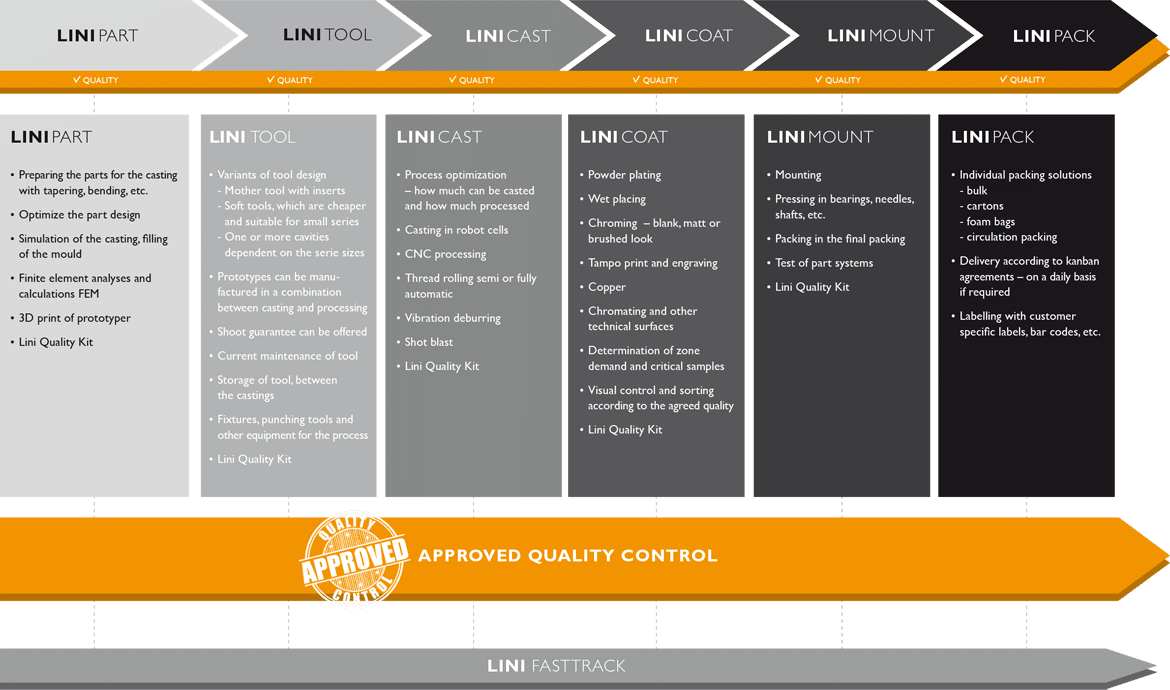

We have the expertise, so if you would like to use zinc, you can use us from sparring about your idea all the way through to production of your finished part, and regardless of whether you will need small or long runs and the specific type of surface treatment. In fact, you can also use us after production, where we offer to assemble your elements from different suppliers and pack them.

We support Great Design – How may we support yours?

Our task is actually always quite simple: We will make your product better. With respect to its quality, finish, durability, functionality, competitiveness and price. We wish to make a great design, and hence we always clarify the expectations and desires as early as possible, because we often can accomplish more with zinc than people can imagine. One of our core competences is our unique quality in surface-treated parts, where we can deliver the agreed quality every time.

To learn what challenges we have previously solved with zinc, please contact us for further details.

We always wish to optimise

We invest in good quality. Our factory was built in 2001, and it houses a flexible, modern production mechanism that is optimised to produce zinc parts in many variants. We typically produce zinc parts in annual runs of between 500 and 500,000 pieces. If you need tools developed, we do this on the basis of computer analysis.

We are very conscious of the fact that we can always be better. Hence we bring in for example experts from outside with new and exciting knowledge, we operate with lean production, and are always actively working to do things better and more efficiently to benefit you as our customer – and thereby also for our own benefit.

Zinc and the environment

Even though zinc has a low melting point in relation to other metals, we are a larger energy-consuming production enterprise. Hence we have a natural on-going focus on reducing our effect on the environment, on energy savings and on the increased recycling of raw materials. And then we switch off our PCs before we go home from the office.

Would you like to know more? Then please contact us here.

View our profile film here.

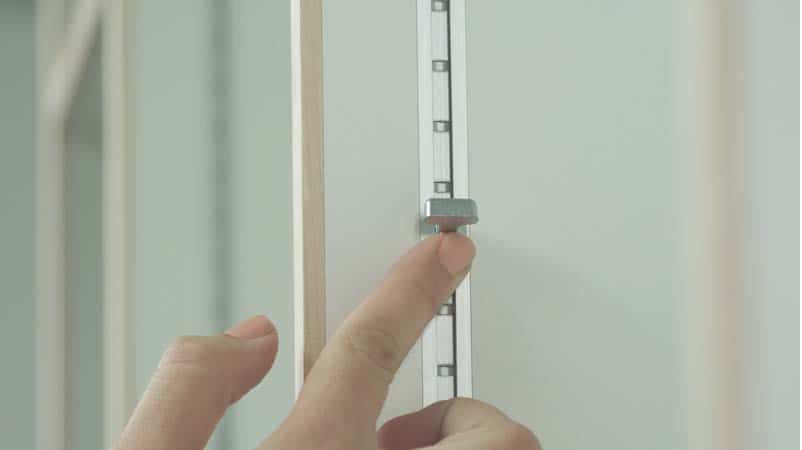

Linitrack

Services

Prototypes and preseries allow you to acquire significant experience early and inexpensively…

The agreement provides us both with added value when we are able to plan based upon forecasts that you provide…

Procure stable casting moulds for large production runs, and let us store them properly…

For special requirements involving finish and durability, zinc is the obvious material…

We deliver natural, high quality with zinc. In addition, we are ISO 9001 certified…

Let us do your assembly work with parts from other suppliers and for example be responsible for the packing and controls…

We support great design

Design

We see it as our task to create Great Design together with you. Hence we wish to optimise the design with respect to its quality, finish, durability, functionality and price. Zinc’s benefits can give you more value. We need to make use of this.

Production

We are always ready to accommodate your desires. With a flexible, modern production setup, we have optimised the production of zinc parts of many variants, sizes and quantities. In addition, we have 24 hour production operation ready for your parts.

Postprocessing

One of zinc’s great benefits is that the need for postprocessing is minimal. However, we can as needed postprocess it with all the current methods such as grinding, punching and CNC machining. In addition, we can perform surface treatments such as chromate plating, lacquering, chrome plating and engraving, providing you with a handsome finish.

Assembly

We can save you the administration, time and money by assembling your production from other suppliers for you. For example, we would be pleased to deliver assembled parts for a finished product, including packing, customer-specific packaging, labelling, quality controls, etc.

Clients