Surface coating

Zinc makes for a smooth finish and longer durability

Zinc is the obvious material when you have special requirements for the surface of die-cast part. Our professional treatment methods also ensure, in addition to a smooth finish in accordance with precise technical specifications, greater durability with respect to, among other things, wear and corrosion.

In addition to our own vast experience into die-casted Zink parts with various coatings, we have close co-operations with leading companies in surface treatment in Denmark and Germany. Such co-operation ensures the best possible service to our customers.

The processes we perform include:

- Electrochemical chromate conversion (Also RoHS compatible surface treatments)

- Chromate conversion before lacquering (pretreatment)

- Polished and brushed chrome plating

- Wet and powder lacquering

- Engraving, laser engraving and serigraphy

If you would like to know more about the specific surface treatments we offer, please contact us.

Please do not hesitate to contact Linimatic to strengthen your solutions and by this optimizing your possibilities.

Jürgen A. Haberl

Salg

Direct: +45 6155 5572

Email: jh@linimatic.dk

We support great design

Design

We see it as our task to create Great Design together with you. Hence we wish to optimise the design with respect to its quality, finish, durability, functionality and price. Zinc’s benefits can give you more value. We need to make use of this.

Production

We are always ready to accommodate your desires. With a flexible, modern production setup, we have optimised the production of zinc parts of many variants, sizes and quantities. In addition, we have 24 hour production operation ready for your parts.

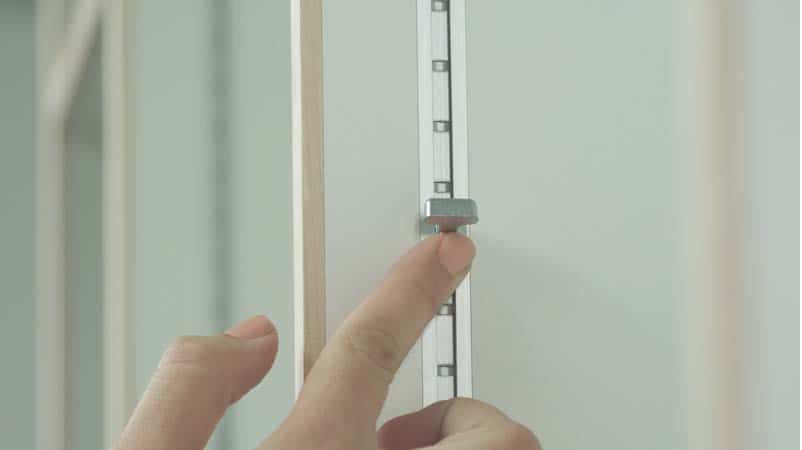

Postprocessing

One of zinc’s great benefits is that the need for postprocessing is minimal. However, we can as needed postprocess it with all the current methods such as grinding, punching and CNC machining. In addition, we can perform surface treatments such as chromate plating, lacquering, chrome plating and engraving, providing you with a handsome finish.

Assembly

We can save you the administration, time and money by assembling your production from other suppliers for you. For example, we would be pleased to deliver assembled parts for a finished product, including packing, customer-specific packaging, labelling, quality controls, etc.

Clients